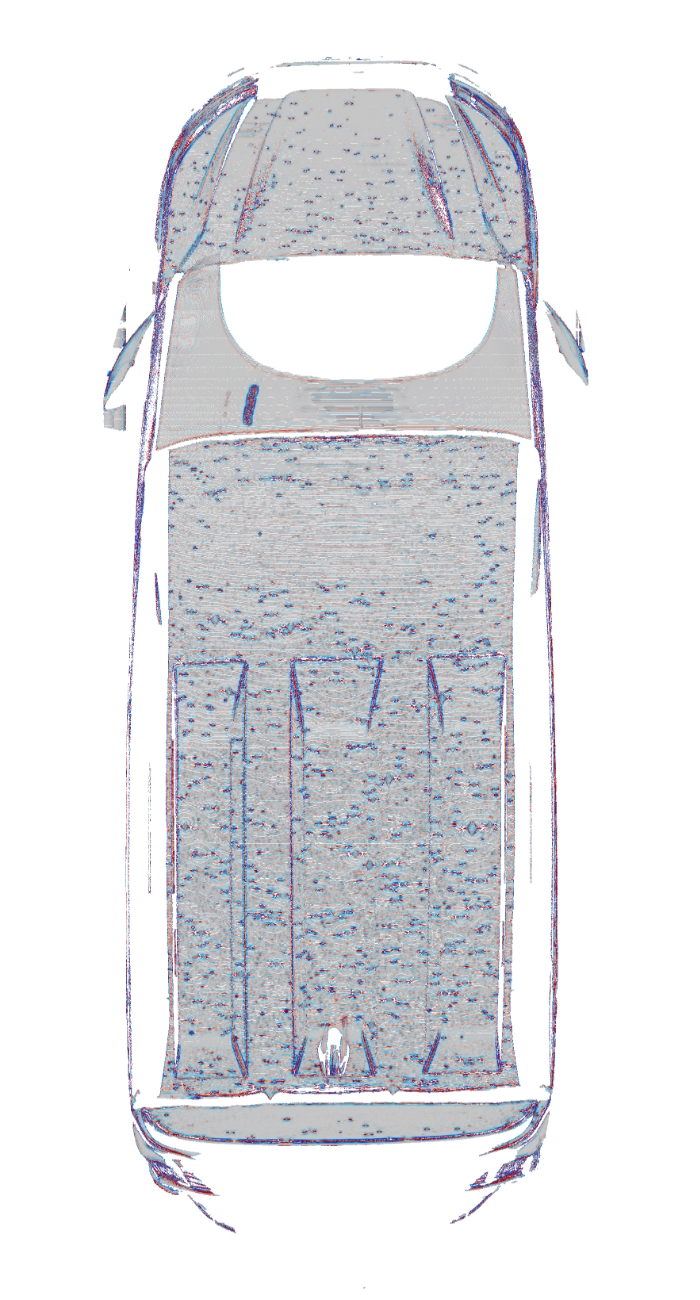

Automated inspection of damages and defects in the industrial production with the ALVISTO system

Our system for quality control of reflective surfaces adresses all challenges that are commonly associated with previous quality inspection systems. No more complex setups, hefty investments, or specific location requirements. ALVISTO is designed for flexibility and easy integration into your existing production processes. This means that manual, and therefore error-prone, visual inspections are not needed anymore. ALVISTO stands out from the competition by utilizing diverse image processing techniques and state-of-the-art artificial intelligence (AI) methods.

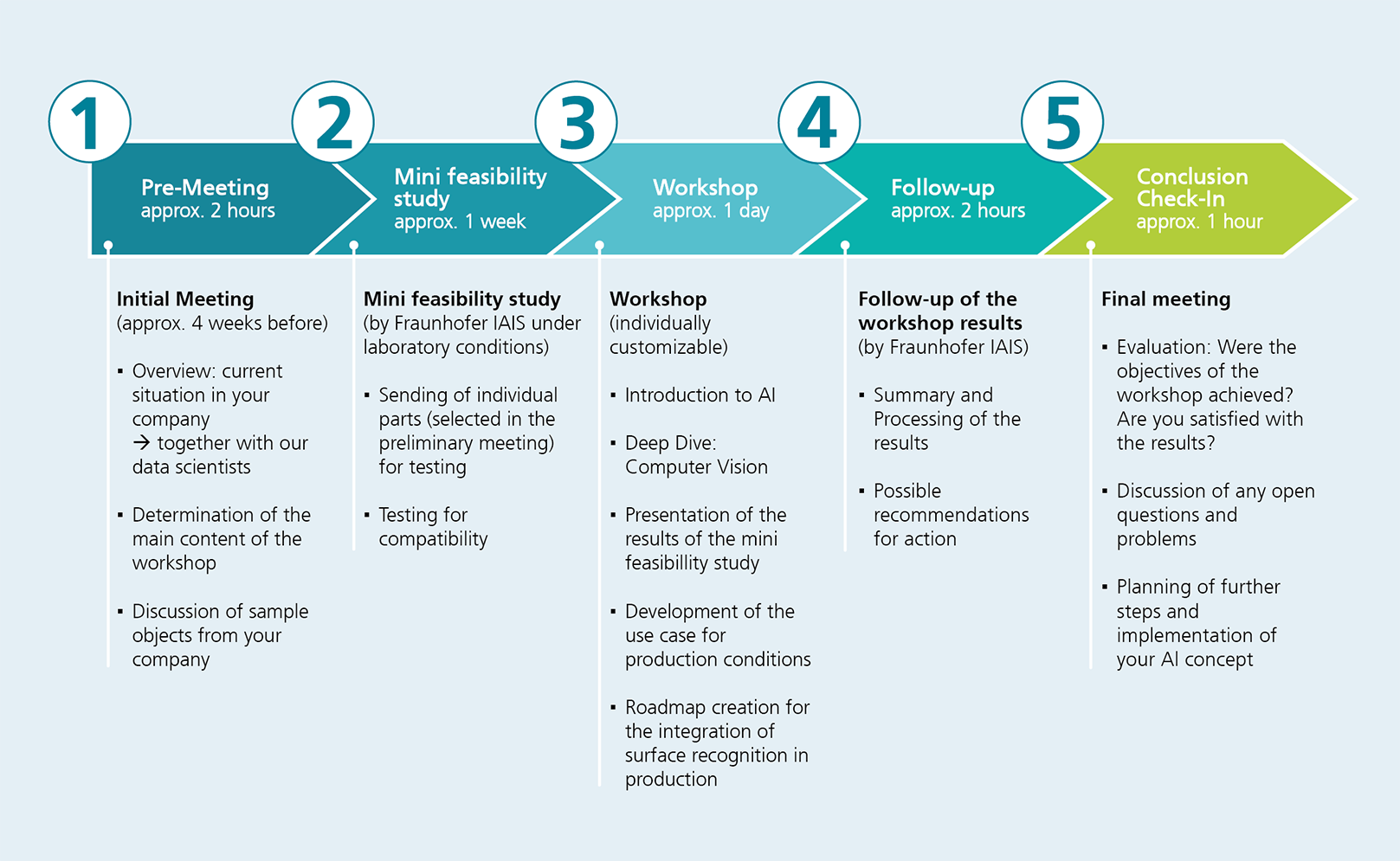

ALVISTO scans the inspected material and then analyzes the video material with the help of AI. Our fully automated system takes less than a minute to inspect the surface with high precision. Utilizing deep learning, we categorize surface defects into individually customizable defect classes, tailored to the specific needs of your industry. A more detailed description of the procedure can be found here.

Flexible design and easy integration

AI-based visual quality control is characterized by a simple, mobile and cost-efficient hardware setup that does not require any special safety precautions or environmental conditions. This allows us to offer you a simple integration in existing productions or even mobile usability — wherever you need.

The 100 percent test coverage and our real-time analysis make it possible to quickly detect quality defects, such as dust inclusions, in industrial production and take appropriate measures early on in the production process before further costs are incurred. ALVISTO is also ideal for inspecting and analyzing damages caused by hail or other impacts.

Individually customizable for your application

In addition to implementing ALVISTO for your individual application, we also offer to retrofit your existing image processing solution with an AI module. We are happy to advise you in optimizing your existing system.